Timing Advance Processor Explained- Maximize Engine Performance and Reliability

A Timing Advance Processor (TAP) is an essential component in modern engines running on alternative fuels such as CNG and LPG. By optimizing spark timing, it ensures efficient combustion, improved performance, and reduced emissions.

Unlike conventional gasoline engines, alternative fuels burn differently, requiring precise calibration for ignition timing. This guide explores the types of timing advance processors, how to select the appropriate one, proper installation procedures, troubleshooting methods, and strategies to maximize engine efficiency and reliability.

Car engine showing Timing Advance Processor Explained, highlighting improved efficiency, better performance, and reliable power output.

Understanding Timing Advance Processors

A Timing Advance Processor is an electronic device designed to adjust the ignition timing of an engine. Engines running on alternative fuels such as CNG or LPG have different combustion characteristics compared to gasoline engines, including slower flame propagation and varying octane levels. TAPs intercept ignition signals and modify them to ensure that combustion occurs at the optimal moment. This adjustment helps prevent knocking, reduces fuel waste, and maintains power output.

The main advantages of using a TAP include improved engine efficiency, smoother acceleration, and adaptability to different fuel types. Many modern TAPs feature programmable functions, emergency bypass capabilities, and compatibility with a wide range of ignition systems. Emergency bypass functionality is particularly important as it allows vehicles to operate safely even if the TAP malfunctions.

Types of Ignition Systems and TAP Compatibility

Understanding your vehicle’s ignition system is essential for selecting the right TAP. There are four primary types of ignition systems.

Mechanical Breaker Point Ignition Systems

Older vehicles use mechanical breaker points and a distributor to control spark timing. These systems rely on physical contacts to open and close the primary circuit of the ignition coil. TAPs for mechanical systems intercept the low-voltage signal from the points to the coil and adjust the timing appropriately.

These processors are simple in design but critical for ensuring that alternative fuel combustion occurs at the correct moment.

Electronic Ignition with Distributor

Electronic ignition systems eliminate mechanical points and use an electronic module to manage timing. TAPs compatible with electronic distributor systems connect to the output of the ignition module.

These processors react faster than mechanical systems, handling higher engine speeds without timing errors. They provide precise control over spark advance and are ideal for engines that have been converted to alternative fuels.

Electronic Ignition with Module

Modern engines often use dedicated ignition modules capable of adjusting timing based on engine speed and load. Reprogrammable TAPs allow technicians to customize timing curves to suit specific engines and fuel types.

This flexibility ensures that the engine operates efficiently under different conditions, whether using CNG or LPG, and can compensate for engine wear or environmental changes over time.

Crankshaft Position (CKP) Sensor Systems

The most advanced engines use CKP sensors to provide accurate timing data to the engine control unit (ECU). These sensors can be inductive, producing an analog voltage signal, or Hall-effect, generating a digital signal.

TAPs compatible with CKP systems process these signals and modify ignition timing for optimal performance. This allows precise control over combustion, ensuring smoother engine operation, better fuel efficiency, and reduced emissions.

Key Factors for Selecting a Timing Advance Processor

Choosing the correct TAP involves considering several technical factors.

The ignition system type of the vehicle is the first consideration. Whether the engine uses mechanical breaker points, an electronic distributor, or CKP sensors, selecting a processor that can accurately process the system’s signal is essential.

Using an incompatible processor may cause engine knocking, reduced performance, or operational issues.

Fuel type compatibility is another critical factor. Some processors are designed to handle only CNG or LPG, while others are dual-fuel capable. Dual-fuel processors provide flexibility for vehicles that switch between fuels, ensuring consistent performance without manual recalibration.

The timing adjustment range of the TAP is also important. Different engines and fuels require different degrees of spark advance. Mechanical systems typically need smaller adjustments, while modern CKP sensor-based systems may require larger timing modifications.

Processors with programmable settings or adjustable ranges offer the greatest flexibility.

Emergency bypass functionality is a key safety feature. In the event of a TAP malfunction, the bypass allows the engine to revert to its original timing settings, ensuring that the vehicle remains operational. This is particularly important for long trips or vehicles used in critical applications.

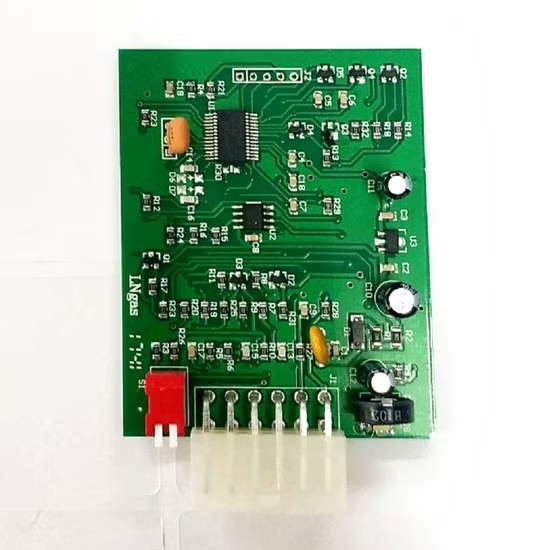

Ease of installation should also be considered. Some processors are simple plug-and-play devices, while others require advanced wiring, signal verification, and calibration. Proper installation is essential for reliable performance and avoiding engine damage.

Installation Procedures

Although installation procedures vary depending on the ignition system, some general steps are common to all processors. The vehicle battery should be disconnected before installation to prevent electrical damage. Identifying the correct connection points based on the ignition system is crucial.

The TAP is connected according to the wiring diagram, and the timing advance is adjusted using the processor’s controls. Finally, the system should be tested under different operating conditions to ensure proper functionality.

For mechanical breaker point systems, the TAP is installed between the distributor and the ignition coil. Proper grounding and mounting away from heat and moisture are necessary. The timing is initially set based on manufacturer recommendations, then fine-tuned using a timing light to verify performance.

In electronic distributor systems, the processor connects inline with the ignition module’s output signal. Correct power and ground connections are vital. Timing adjustment is achieved using onboard potentiometers or DIP switches, and engine performance is monitored across different speeds.

For CKP sensor-based systems, the processor is connected inline with the sensor signal wire, maintaining proper polarity and shielding to avoid signal interference. An oscilloscope is used to verify signal integrity, and timing adjustments are made to match engine RPM and load requirements. Testing across the full RPM range ensures consistent performance.

Troubleshooting Common Issues

Engine knocking when running on alternative fuels may indicate insufficient timing advance. Adjusting the timing slightly earlier can resolve this issue. Poor acceleration may result from excessive timing advance, which requires reducing the setting.

If the engine fails to start, wiring errors or loose connections are often the cause. Rough idling can occur if the idle bypass is set incorrectly, which can be corrected by adjusting the processor. If the TAP is unresponsive, power supply issues, including improper grounding or low voltage, should be checked.

Emergency connectors allow technicians to bypass the TAP if problems occur, restoring original ignition timing. This ensures the vehicle remains operable and provides a baseline for troubleshooting or recalibration.

Optimizing Performance with Alternative Fuels

Alternative fuels such as CNG and LPG have unique combustion properties that influence ignition timing. CNG, with its higher octane rating, allows for more aggressive timing advance but requires earlier spark to compensate for slower flame propagation.

Its cleaner combustion reduces the tendency for engine knock. LPG, on the other hand, has vaporization characteristics similar to high-grade gasoline. Timing adjustments must account for fuel delivery and storage pressure to optimize combustion and engine performance.

Proper TAP selection and calibration can significantly enhance fuel efficiency, increase power output, and reduce emissions. Engines tuned with precise timing advance for alternative fuels perform smoothly across all RPM ranges, contributing to better driving experience and lower long-term operational costs.

Benefits of Using a Timing Advance Processor

- Improved Engine Performance: Ensures ignition occurs at the optimal moment for smoother acceleration and increased power output.

- Enhanced Fuel Efficiency: Optimizes combustion, reducing fuel wastage and improving overall mileage.

- Reduced Emissions: Promotes cleaner combustion, lowering harmful exhaust pollutants.

- Adaptability to Alternative Fuels: Supports CNG, LPG, or dual-fuel setups for consistent engine performance.

- Safety Features: Emergency bypass functionality allows continued vehicle operation if the processor fails.

- Customizable Timing: Programmable or adjustable processors allow fine-tuning for specific engines and fuel types.

- Reliable Operation: Maintains engine efficiency across different RPM ranges and load conditions.

FAQs

1. Can a TAP improve fuel economy?

Yes. By optimizing ignition timing for alternative fuels, a TAP ensures more complete combustion, which improves fuel efficiency and reduces operational costs.

2. Are TAPs compatible with all engines?

While many processors are universal, compatibility depends on the vehicle’s ignition system and fuel type. Using an incompatible processor may reduce performance or cause engine issues.

3. How often should a TAP be recalibrated?

Periodic recalibration is recommended, especially if engine wear, fuel type, or operating conditions change. Regular checks help maintain optimal timing and engine performance.

4. Can I install a TAP myself?

Installation complexity varies by system type. Mechanical systems may allow DIY installation, but modern electronic systems with CKP sensors often require professional setup to ensure accuracy and avoid damage.

5. What happens if a TAP fails?

Most TAPs include emergency bypass functionality, allowing the engine to operate using factory timing. This ensures the vehicle remains operable while troubleshooting or replacing the processor.

Conclusion

A Timing Advance Processor is essential for maximizing engine performance, fuel efficiency, and emission control in vehicles running on CNG and LPG. Selecting the correct processor, installing it accurately, and maintaining it ensures smooth operation and safety. Properly calibrated TAPs enhance power, reduce fuel consumption, and enable cleaner combustion, offering long-term benefits for both everyday driving and high-performance applications.